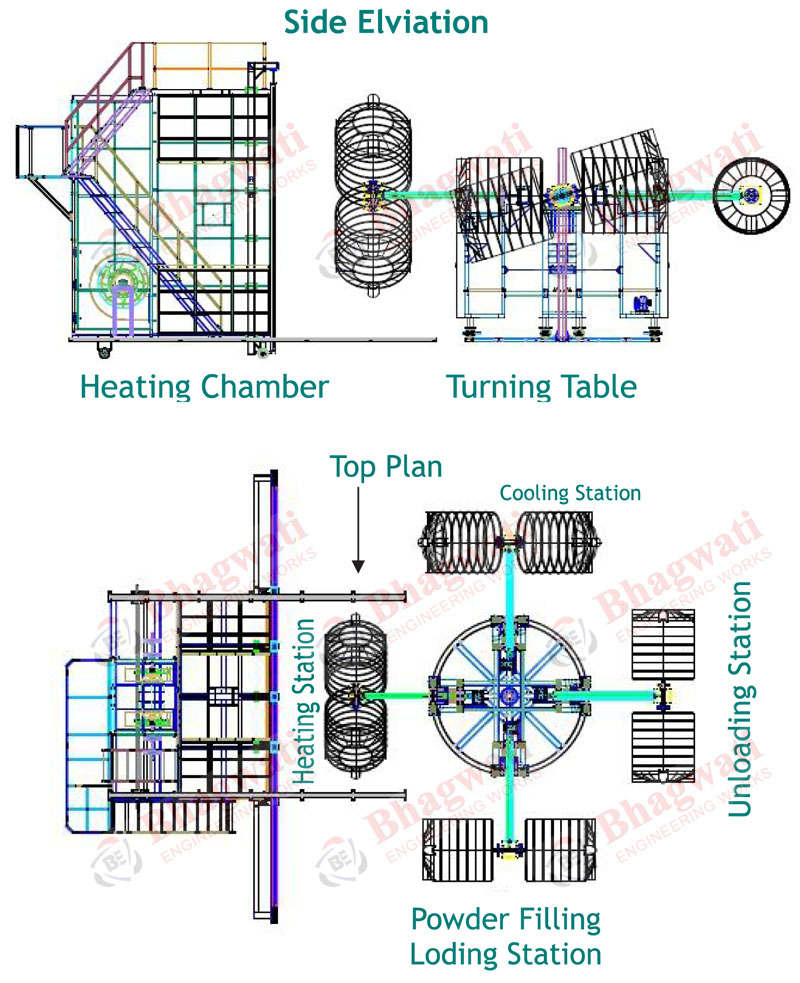

Bi Axial Rotational Moulding Machine is mostly used to produce water tank & Product in Mass production . Fixed Three/Four Arm work in process at a same time like Heating , cooling, unloading, loading time can be provide to save time.

Machine Main Feature

- Bi Axial rotational moulding Machine Technology is used to save fuel consumption , power HP and to produce mass production in water storage Tank and other industrial Product.

- Machine at a time works in four process Heating, Cooling, Unloading And loading . So in this way machine work in multi tasks to save energy,Man power, and gives mass production.

- In Bi axial machine mould turn round in 360 degree in rotation in Major and Minor axis So product wall thickness will be equal at all side.

- Bi Axial machine burner have auto ignation system with temprature controllar system, and Hot air circulation system So hot air circulate on mould surface equal and product will be produce in good quality and equal wall thickness.

- Electrical Panel is Easy to operate and equiped with saftey featured, indicator, Alarm system .

- Microprocess or PLC based with degital dispaly controll panel can be provided Optional on Request.

- Bi Axial machine is available with Oil/gas/CNG fire burner.

- High Density insulation material for High performance.

- In Offset Arm interchangable mould weight balancing facility available.

- Strait Arm has four individual mould carrier facility for equel wall thickness.

- As per product required process time machine is available in Three/Four arm model.

Machine Models

| No | Model | Area Require LXWXH (Feet) |

Power HP |

Cooling Fan HP |

Production per 12 Hours |

| 1 | BE2000X1 | 40 X 30 X 25 | 28 HP | 2 + 2 | 45000 Liters |

| 2 | BE1000X4 | 40 X 40 X 30 | 32 HP | 2 + 2 | 78000 Liters |

| 3 | BE5000X1 | 50 X 40 X 30 | 38 HP | 3 + 3 | 90000 Liters |